What is a Xbar S Chart?

The X-S chart (also called Xbar S chart) is a control chart for continuous data with a constant subgroup size greater than ten. The Xbar chart plots the average of a subgroup as a data point. The S chart plots the standard deviation within a subgroup as a data point.

The Xbar chart monitors the process mean and the S chart monitors the variability within subgroups. The Xbar is valid only if the S chart is in control. The underlying distribution of the Xbar-S chart is normal distribution.

Xbar Chart Equations

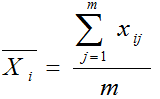

Xbar Chart

Data Point:

Center Line:

Control Limits:

![]()

Where:

- m is the subgroup size

- k is the number of subgroups

- A3 is a constant depending on the subgroup size

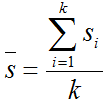

S Chart Equations

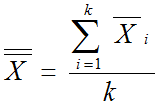

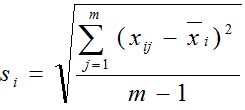

S chart

Data Point:

Center Line:

Upper Control Limit:

![]()

Lower Control Limit:

![]()

Where:

- m is the subgroup size

- k is the number of subgroups

- B3 and B4 are constants depending on the subgroup size

Use Minitab to Plot Xbar-S Charts

Data File: “Xbar-S” tab in “Sample Data.xlsx”

Steps to plot Xbar-S charts in Minitab:

- Click Stat → Control Charts → Variables Charts for Subgroups → Xbar-S.

- A new window named “Xbar-S Chart” appears.

- Select “Measurement” by clicking the box below

“All observations for a chart are in one column” - Select “Subgroup ID” as the “Subgroup Sizes.”

- Click the button “Xbar-S Options” to open a window named “Xbar-S Chart Options”.

- Click the tab “Tests.”

- Select the item “Perform all tests for special causes” in the dropdown menu.

- Click “OK” in the window “Xbar-S Chart Options.”

- Click “OK”.

- The Xbar-S charts appear in the newly-generated window.

Xbar-S Charts Diagnosis

Model summary: Since the S chart is in control, the Xbar chart is valid. In both charts, there are not any data points failing any tests for special causes (i.e., all the data points fall between the control limits and spread around the center line with a random pattern). We conclude that the process is in control.

Comments are closed.